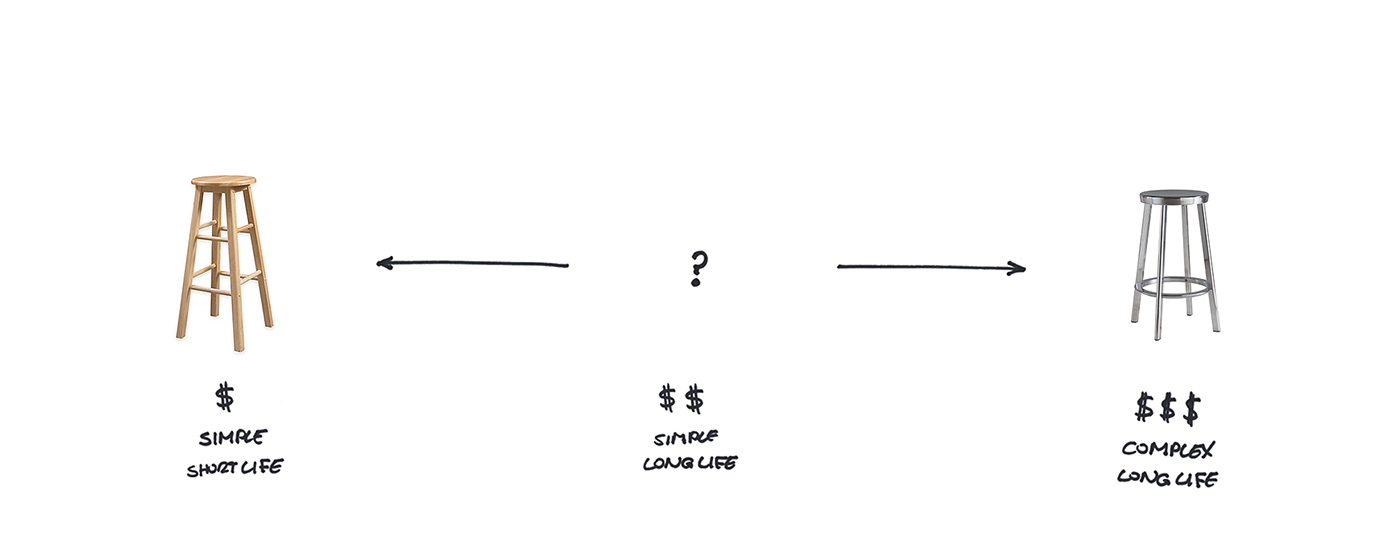

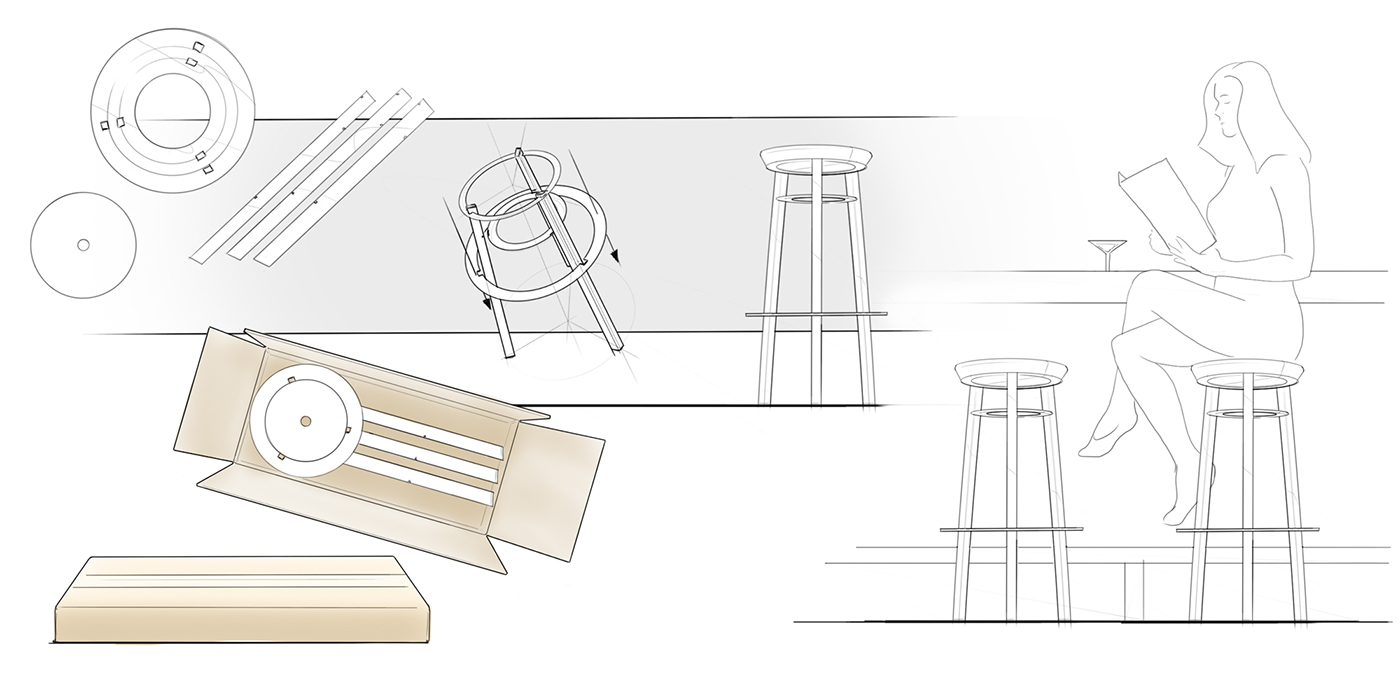

A flat-pack aluminium stool. Utilizing easily sourced materials and scalable manufacturing processes the stool aims to be a cost effective object of utility that lasts a lifetime. The configuration allows for flat pack shipping and simple assembly.

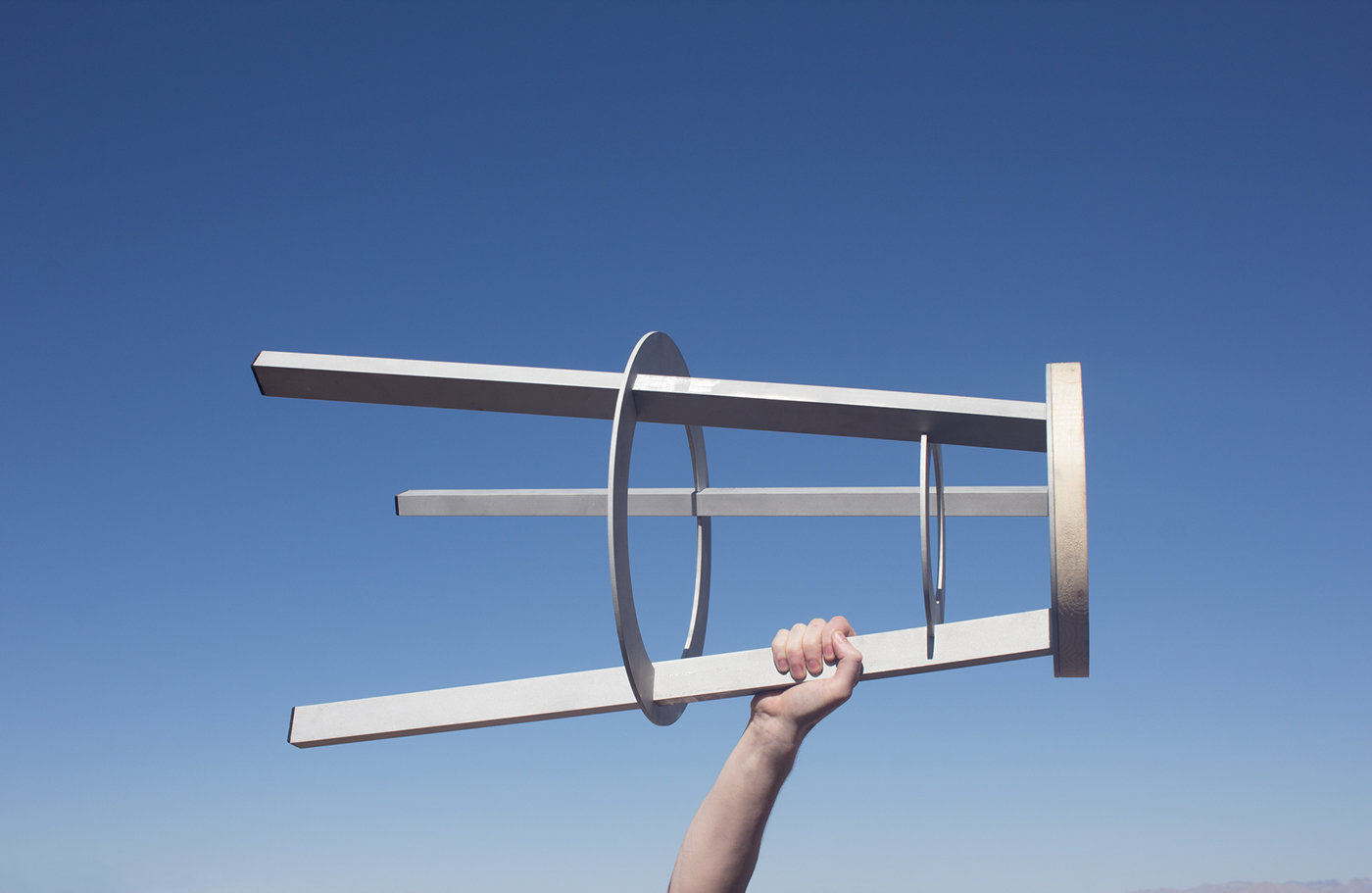

The stool remains true to its creation in allowing function to drive form. It's raw and simple, celebrating the manufacturing and materials that allow it to exist. The aluminium is sandblasted, then anodized to create a tough surface that is accepting of the scuffs and scratches that inevitably collect over the years. It also proudly displays the marks of assembly created by the interference fit.

The frame originated from an idea to use interference as a means of producing structural integrity; and what that could mean for flat-pack furniture. Stock raw materials are minimally processed by waterjet and mill to create components requiring no tools for assembly.

Functional prototype

When assembled the legs are held with a slight flex. This acts to create an internal force that ensures everything stays together. Traditional flat-pack furniture loosens at the fixtures with use - here those same forces actually contribute to the structural integrity.

A more triangular form factor was developed after detailed testing of the functional prototype. This improvement solves for a potential tipping issue, as well as improving raw material efficiency allowing more components to be cut from the same sheet.