Engineering: Centriquip

Work placement at centrifuge manufacturer

Work placement at centrifuge manufacturer

Below are examples of two engineering projects I worked on whilst on placement at Centriquip Ltd 2007 to 2008. These were both live projects The first is a modification to the concrete base of a centrifuge and the second is a Nitric acid resistant bearing seal.

Project 1: Concrete centrifuge base

The Problem: The concrete base of this Centrifuge had failed. This had become a common occurance of this design and needed to be improved.

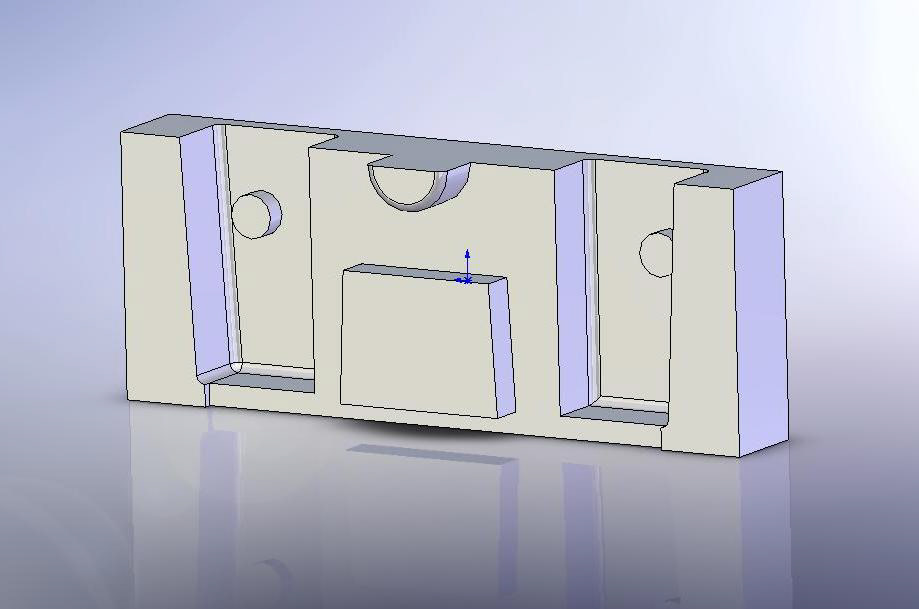

CAD model of how the concrete base used to look. From the first image, it was clear that the Motor mounts weren't strong enough.

The existing mold from which the base was cast in concrete. The mold unbolts and separates into 3 pieces to allow removal of the product. This was useful as it meant one of these smaller pieces of the mold could be replaced, rather than have a completely new mold manufactured.

The new mold piece which would retro-fit the current mold to produce the new design.

Cad model of the new concrete base design. The motor mounts have been significantly strengthened by adding more material. As this new base was designed to be retro-fit, nothing else needed to be changed or positioned differently.

Project 2: Bearing Seal Design

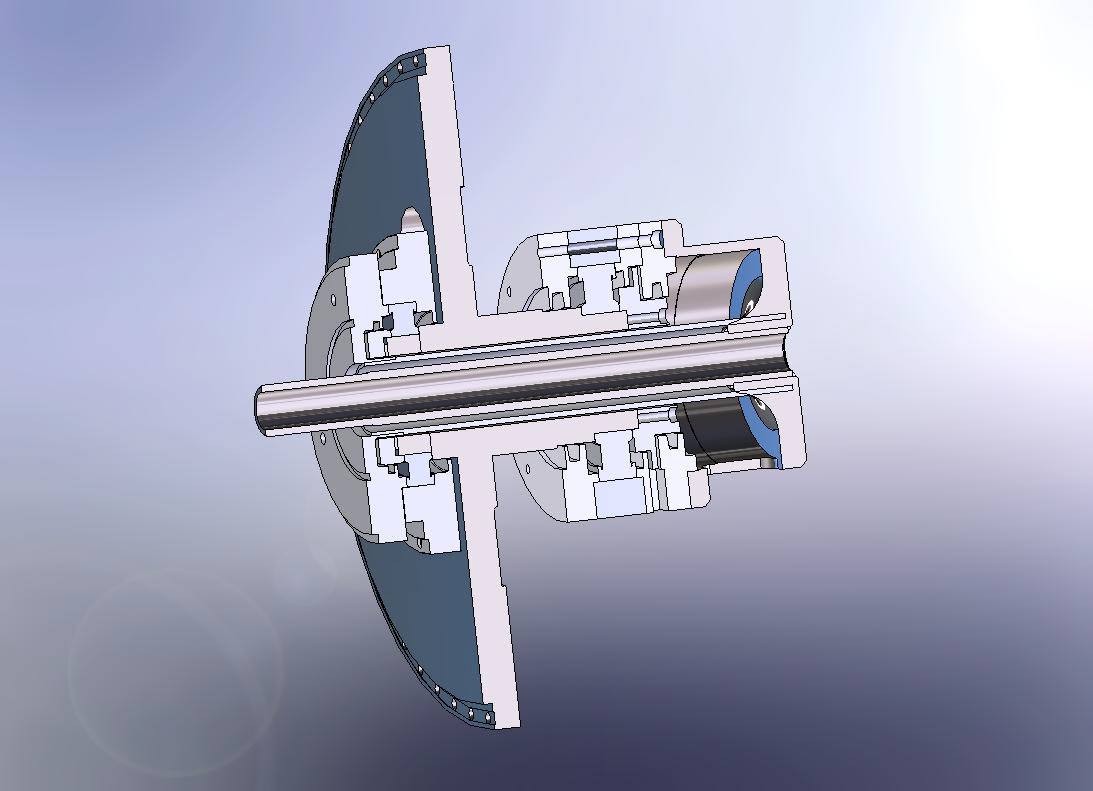

Rotating bearing seal concept that would protect load bearings in a centrifuge from contamination which causes them to fail.

A load bearing from a centrifuge that was due for replacement. Eventually the seals wear and contaminants get into the bearing units causing them to fail.

Section view of the existing design. This used a single outer felt seal to protect the bearings from contaminants. The felt seal usually lasted reasonably well in normal applications.

Basic concept of new seal design: Two outer seals used in conjuction with an additional inner seal. Outer seals remain stationary, whilst inner seal would spin with the centrifuge, forcing it tight against the casing. The design would also have a constant grease feed and drain hole to help keep it sealed.

New seal replacing old system. A number of new parts were designed so that the new seal design could easily fit with current components.