Sustainabike - a work in progress

The aim of this personal project is to design a mass-manufacturable, sustainable, and cheap bicycle. As this is a work in progress images and video will be added at each stage (newest at the top) showing development.

If you have any positive criticism, ideas, feedback, or input, please get in touch via the contact page.

The aim of this personal project is to design a mass-manufacturable, sustainable, and cheap bicycle. As this is a work in progress images and video will be added at each stage (newest at the top) showing development.

If you have any positive criticism, ideas, feedback, or input, please get in touch via the contact page.

First complete prototype. Initial impressions are good, though there of course already areas that need improvement. The fork is for testing only, and will eventually be replaced with a plywood fork designed using the same principals as the frame. Componentry begged, borrowed, and bargained from various sources.

Detail shots. Clockwise from top left: Seat tube junction showing countersunk bolts. Fitted headtube. Rear end with super short 385mm chainstay, note the beautiful woodgrain.

First prototype in the wild, just before field testing.

Steve at Cofa Engineering was pivotal in developing the plywood bike, providing advice and welding services along the way. Heres a video with him, featuring the finished plywood bike.

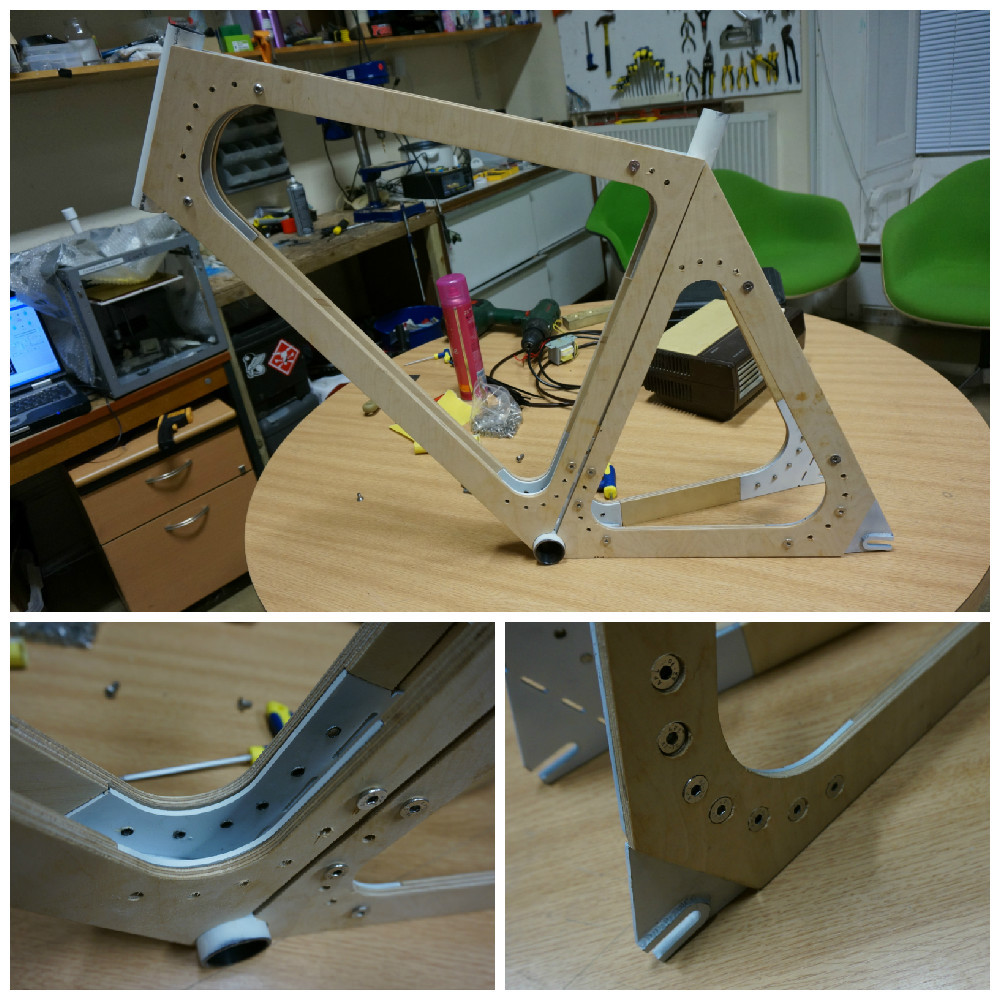

First test build of the frame. Still some fine detail work to do to make it all fit.

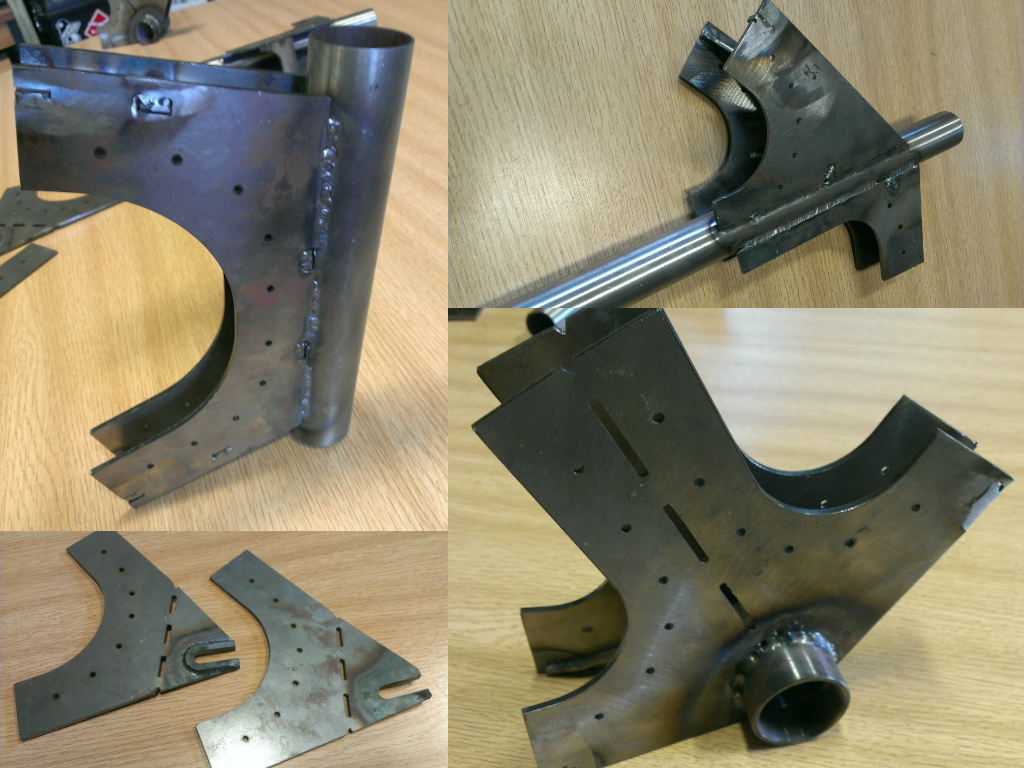

Steel brackets fresh from the fabricator. These still need the holes drilling the correct size and threading. Next the plywood will be cut, and a basic bike build will be completed- probably a fixie for simplicity.

Clockwise from top left: Headtube bracket, Seattube bracket, Bottom bracket, Rear dropouts.

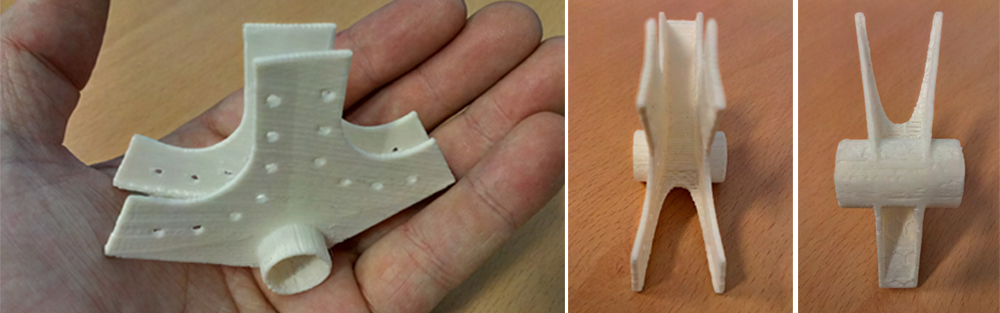

Left to right: Bottom bracket general view, top rear view, bottom view.

The computer based 3D modelling for the first prototype is complete, so now it's time to start making it. Above is shown a half (1:2) scale 3D printed model of the bottom bracket. This low resolution print was made as a quick way to see what it will look like and get a basic idea of strength. I have 1 or 2 concerns, however I have decided to continue without modifying the design as I think once it is manufactured in steel it will be strong enough. It can also be strengthened later if necessary.

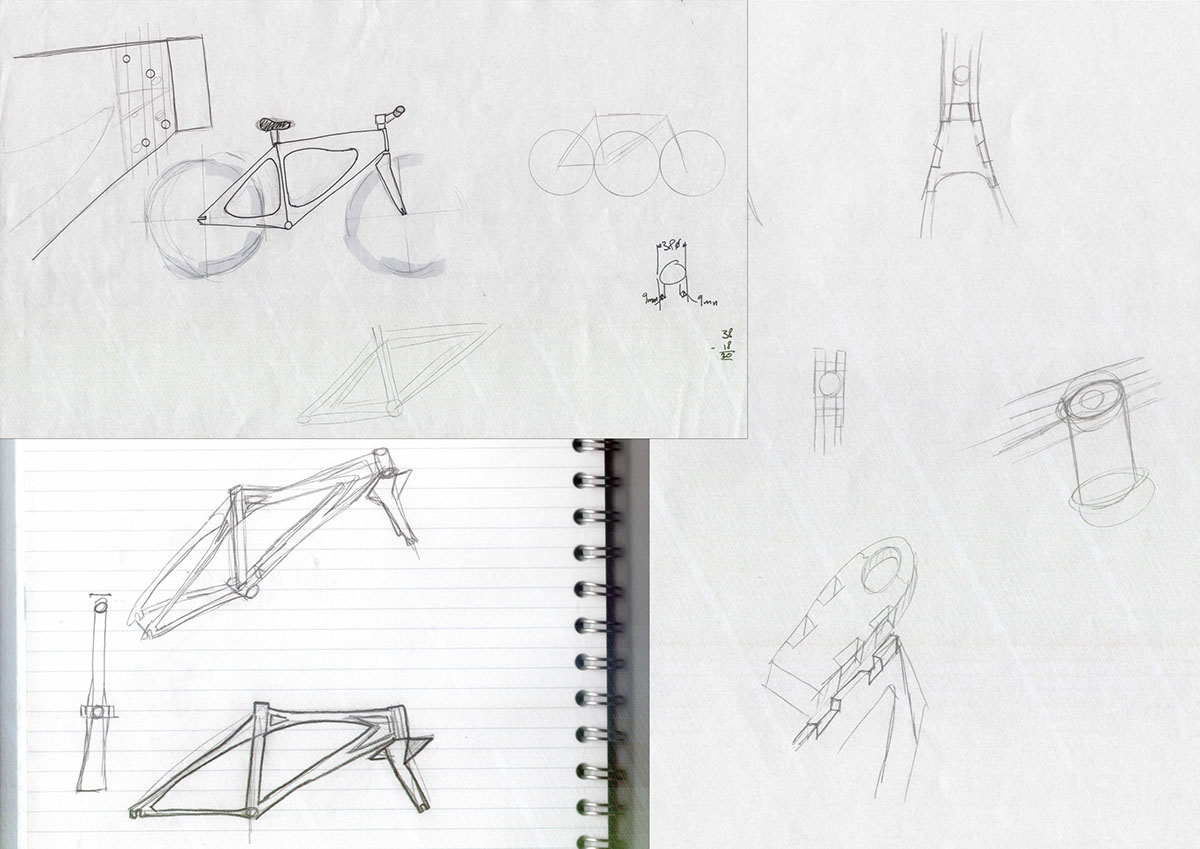

Upon reflecting on the design and looking at trends, I have decided to use larger wheels and base the design more on a road bike. The image above shows this new design complete with forks to compliment the design.

Early render of complete frame (above) and exploded view (below). Theres still lots of details to add but its getting there. Not sure how well it's going to work or even if it's going to work, but looking forward to finding out.

Early stages of CAD modelling in which the geometry and parameters are defined. With the basic concept worked out, technical details and complexities are now worked out. This is still very much in concept development stages.

Early bottom bracket junction (top) and assembly layout with draft lines (bottom).

Early bottom bracket junction (top) and assembly layout with draft lines (bottom).

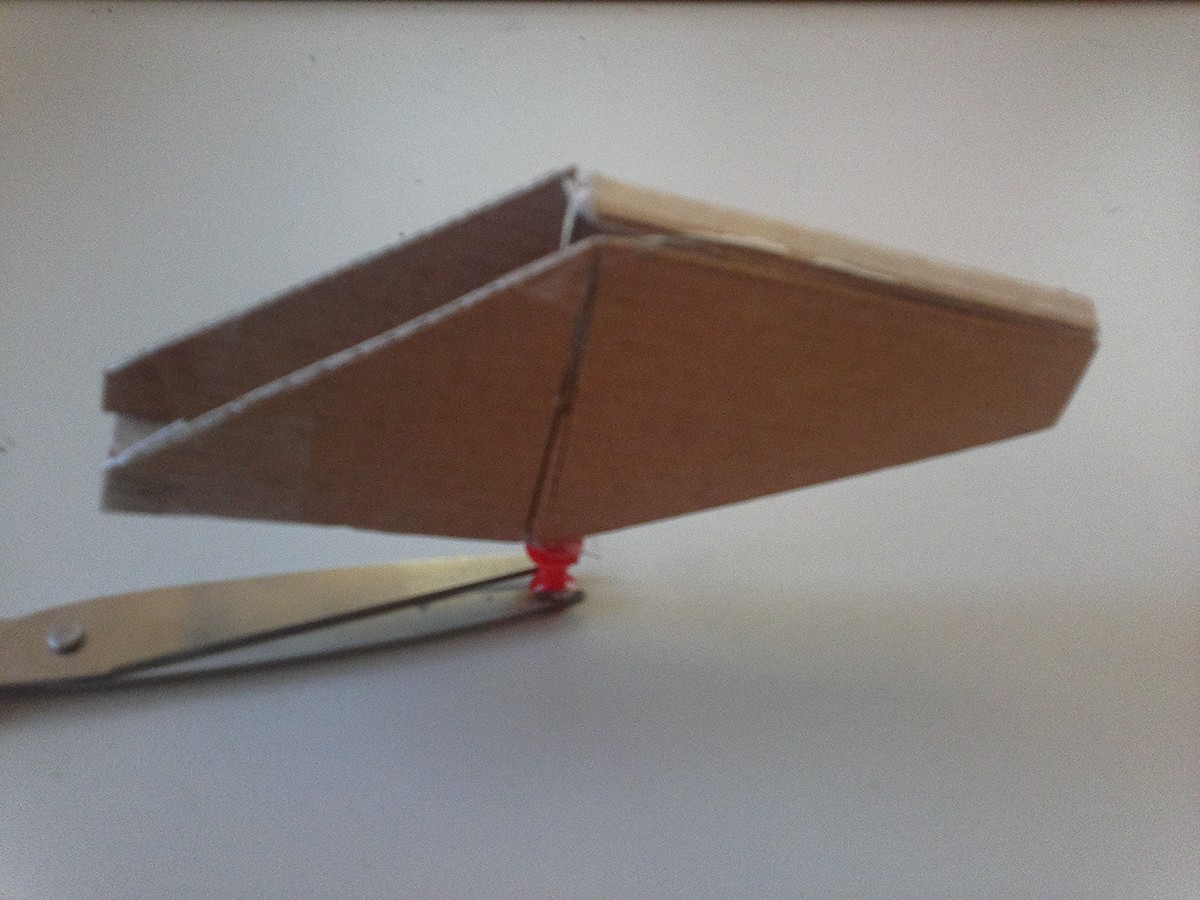

Simple card model to test one of the main principles of the design to use 4 main triangles (above) and the parts laid out (below)

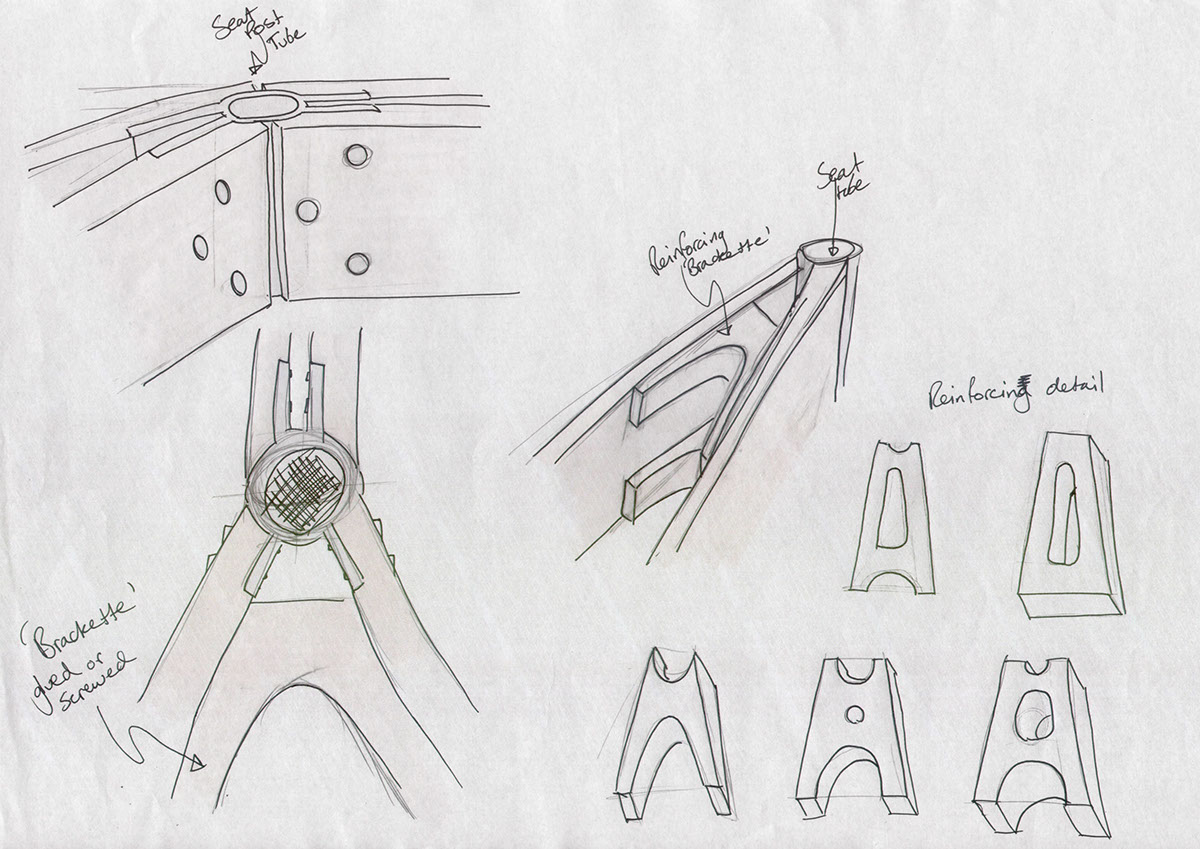

Details: Seat-post junction (top left) and ideation sketching of junction reinforcement details (rest of sheet). Different reinforcement shapes would give different characteristics, better strength/stiffness or better tyre clearance, etc.

Details: This bike isn't designed to look like a bike made out of wood in a shed, its designed to look and ride like a real bike. To do this, all the joints and junctions must be strong and durable, yet unobtrusive.

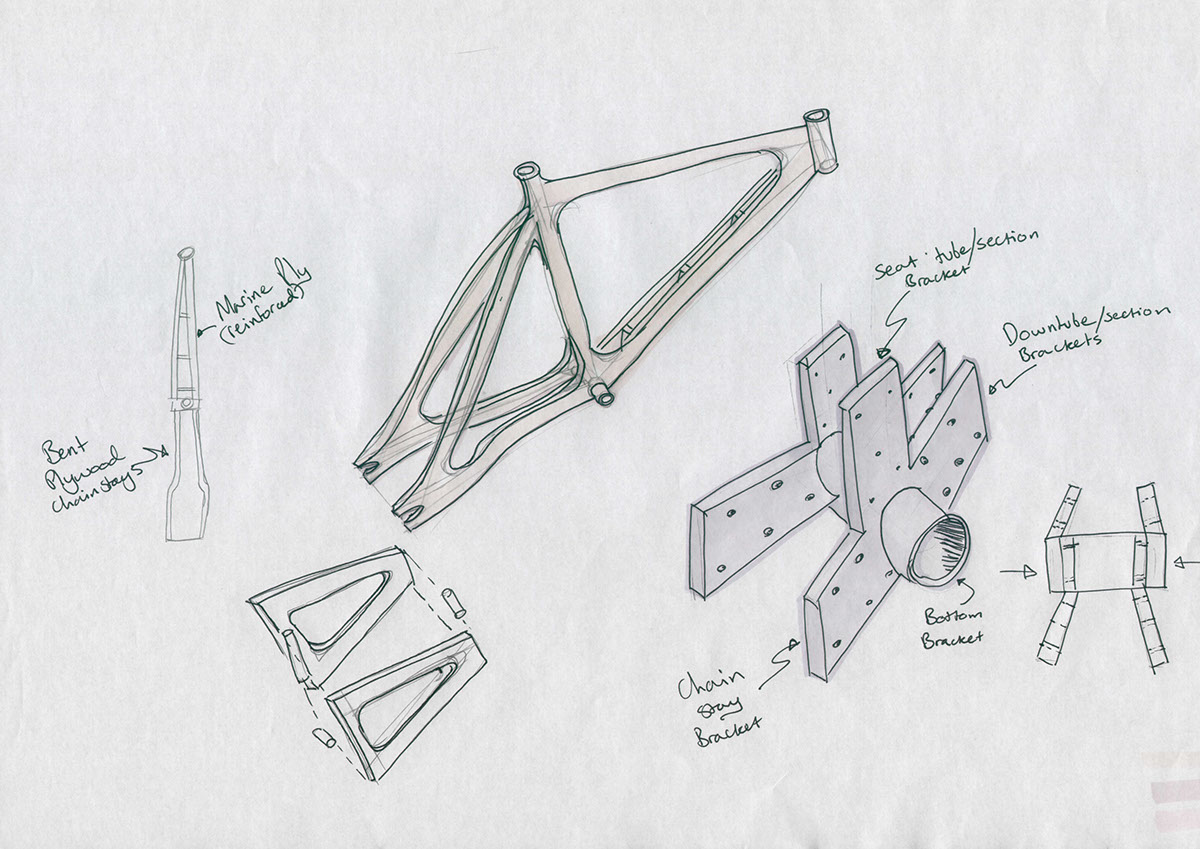

Early drawing of a complete assembled frame concept (left) and basic exploded diagram (right).

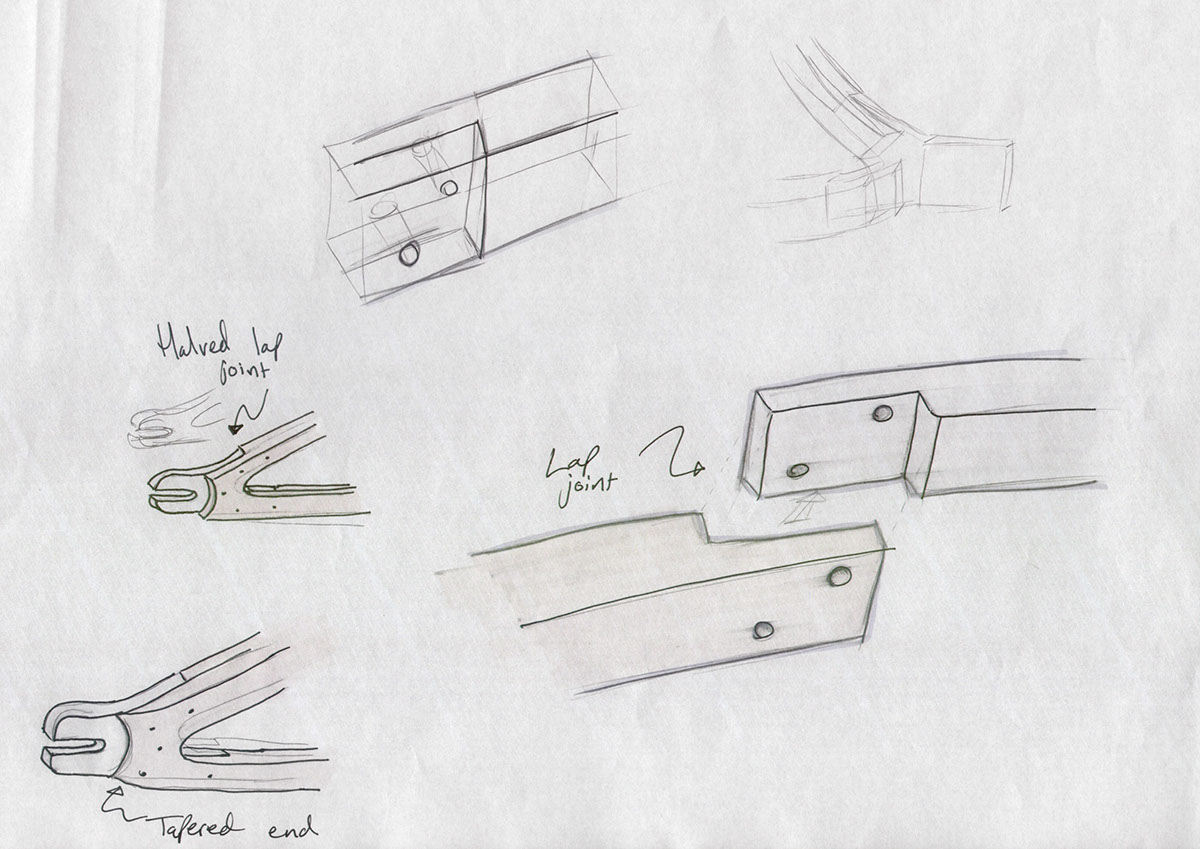

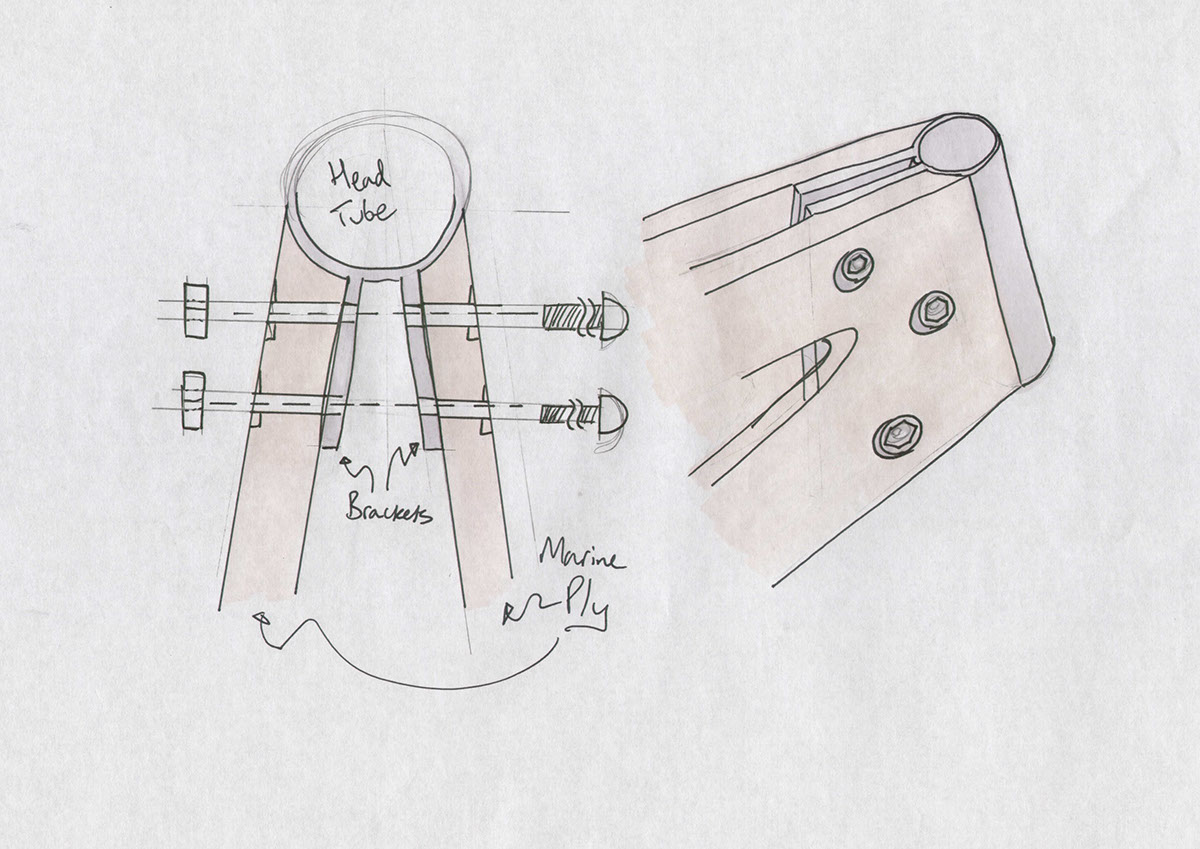

Headtube construction top view (left) and assembled headtube junction (right). Note shaped ends of wood to blend into tubing.

Ideation sketching exploring frame form, construction, and assmbly. This concept would use bent plywood and only 2 main pieces of plywood. Top view assembly (left), complete assembly (middle), bottom bracket example junction (right), early exploded view (bottom).

Getting the idea on paper before its forgotten: Initial ideation sketching. Shape (top left and bottom left), and construction using finger joints (right). The use of finger joints was written off early on as it would over-complicate the design. Integrating the tubing into the wood was explored here, idea that would stay.